CALL SALES: 518-797-3791

CALL SALES: 518-797-3791

Top Tips to Get the Most out of your Spring Rewind Reel

Posted on 08/31/2020

Spring rewind reels save time and effort by simplifying pickup and storage, so that you and your crew can move on to the next job faster. These reels can last a lifetime if they are used and maintained properly. Check out our top tips for getting the most out of your spring rewind reel.

Proper Installation and Set Up

Proper installation of your hose or cable on a spring rewind reel will ensure your reel operates smoothly and has the correct tension set for the length you’re using. Depending on your reel model and spring type, installation techniques may vary.

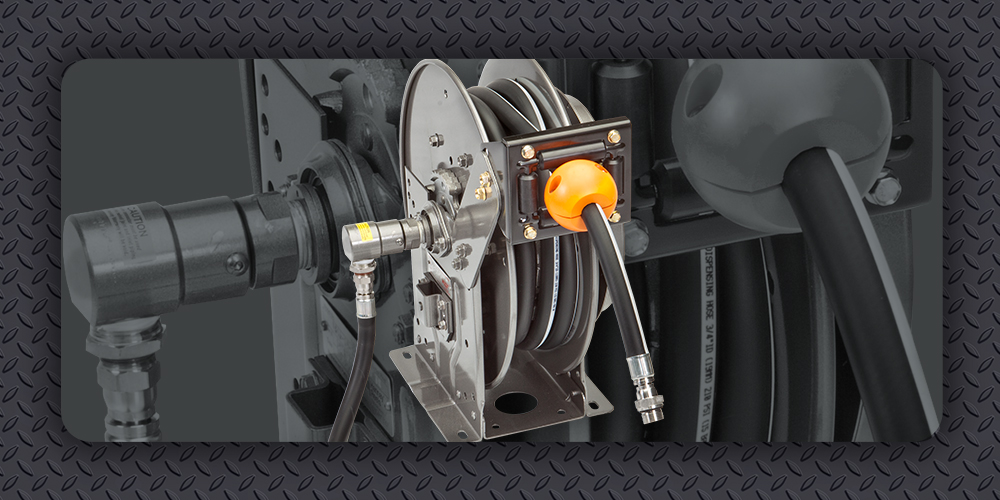

For hose reels, always be sure to use a flexible connector between the inlet pipe and swivel joint. A misaligned hard-piped connection can add side load forces that lead to premature failure of the swivel joint and other parts of the hose reel. For spring rewind cable reels, always use a reel properly rated for the application. Never exceed the voltage and amperage specified for a particular reel or cable.

Check out our step-by-step installation video below, so you can be sure you're setting up your reel correctly.

Rewind the Right Way

While it’s convenient to have a spring rewind reel to help retract your hose or cable, one of the most important rules to ensure the longevity of your reel is to walk the hose or cable back to the reel when rewinding. Never allow it to snap back on its own. The force of the hose or cable snapping back on the reel can damage the spring rewind canister or ratchet assembly unit and can also cause personal injury to you or anyone nearby. While rewinding, it’s important to make sure you distribute the hose or cable back on to the reel as evenly as possible. This step will ensure you are guiding it and not letting it snap back freely.

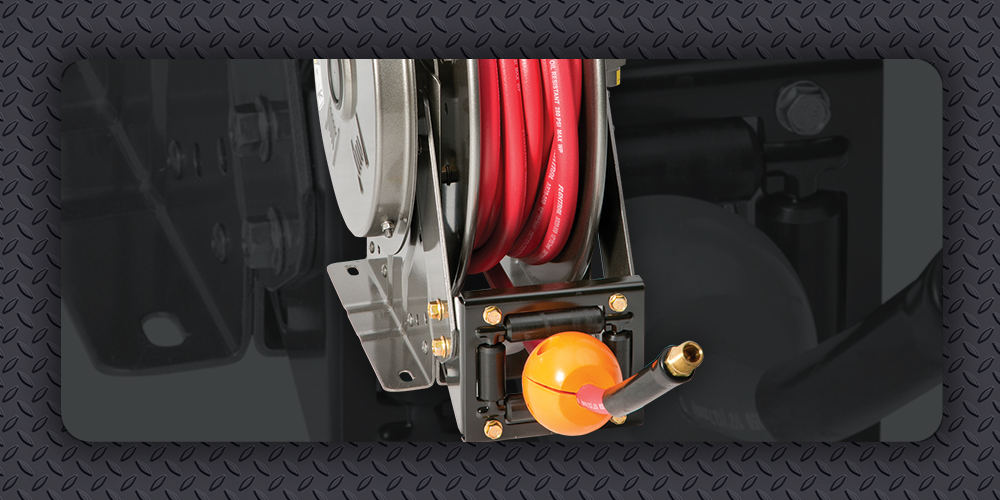

Install a Ball Stop

Except for “constant tension” applications where the end of the hose or cable is tethered or otherwise secured, it’s recommended that a ball stop be used with your spring rewind reel. Having a properly sized and installed ball stop on the reel can prevent damage to the nozzle, fitting, connector or tool that is installed on the end of the hose or cable. For any vertical lift operations, you’ll want to ensure that you are positioning the ball stop so that there is adequate access to the hose above.

Please note that having a ball stop installed on a reel does not negate the requirement to always walk the hose or cable back to the reel in a controlled way.

Stay Up-to-Date on Swivel Joint, Collector Assembly and Motor Maintenance

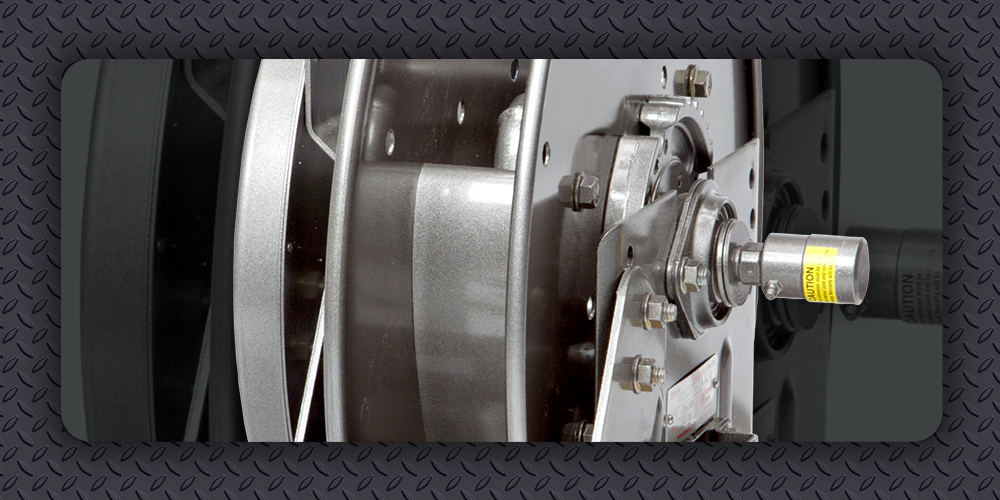

The swivel joints installed on your spring rewind hose reel are pre-lubricated at the factory; however, it’s recommended to re-lubricate the swivel joint per the manufacturer’s instructions. Generally, if you notice a decline in performance, it’s probably time to re-lubricate.

If you are using a spring rewind cable reel, the stationary brushes in the collector assembly may get worn down. When this happens, the brushes will cease to make good contact with the moving collector rings and you will need to replace them. Your collector assembly might be 3-conductor, 4-conductor or even higher, but the procedure to replace it will be very similar.

Replacing a spring motor may also be necessary at some point in the life of your reel. For safety purposes, damaged spring motors should always be replaced. Your spring rewind reels are manufactured with an enclosed spring rewind canister; never remove the cover containing the spring. Coiled springs are under tension and removing the cover can result in severe personal injury.

Rollers and Roller Positions

Hannay’s spring rewind reels offer a variety of roller positions, making them highly versatile. If your needs change, it’s very simple to mount your reel differently. If you’re changing from a floor or wall mount to a ceiling mount, be sure to consult the factory, as you may need different roller brackets or a different spring to allow for the proper lift adjustment.

Our spring rewind reels are designed to be highly versatile and extremely safe. Check out the N700 Series video below and learn about one of our most popular models.

We offer detailed information and support materials on the installation and maintenance of our reels at www.hannay.com.

Share This

Industries: General Education

Applications: General Education

Industries

Applications

- All

- Air / Pneumatic Tools

- Audio / Video / Fiber Optic

- Booster Hose (Fire Protection)

- Breathing Air

- Cable Storage Only (Not Live)

- Chemical / Corrosive

- Electric Cord

- Fire/Rescue - Electric Cord

- Fire/Rescue - Hydraulic Tools

- Fire/Rescue - Utility or Breathing Air

- Flat Hose (Fire Protection)

- Food/Beverage Grade

- Fuel - DEF

- Fuel - LP Gas

- Fuel - Petroleum/Gas/Diesel

- Grounding (Static)

- Grounding (Utility)

- Hydraulic Tools

- Jetting/Water Blasting

- Lawn Care/Spray/Pest Control

- Lubrication / Grease

- Pest Control

- Pipeline Inspection (Video)

- Pressure Wash / Washdown

- Refueling (Diesel/Gas)

- Spray

- Vacuum/Suction

- Water Supply

- Welding - Arc

- Welding - Gas

- General Education